Business Parts

Production Capacity (Jinhae)

| Line | Standard | Capacity (ton) | Remarks | |

|---|---|---|---|---|

| Month | Year | |||

| Green sand mould | 700 * 600 * 250/250 | 1,250 | 15,000 | KOYO/Japan |

| Furan | 20TON / Hour | 250 | 3,000 | OMEGA/England |

| subtotal | 1,500 | 18,000 | ||

| Shell mold | 650 * 520 * 500 | 200 | 2,400 | |

| Total | 1,700 | 20,400 | ||

Production Capacity (Milyang Factory - planned to be moved in 2016)

| Line | Standard | Capacity (ton) | Remarks | |

|---|---|---|---|---|

| Month | Year | |||

| Green sand mould | 700 * 600 * 250/250 | 3,000 | 36,000 | KOYO / Japan |

| 700 * 900 * 350/350 | Under review / Japan | |||

| Furan | 10TON / Hour | 1,000 | 12,000 | Under review |

| 10TON / Hour | ||||

| subtotal | 4,000 | 48,000 | ||

| Shell mold | 650 * 520 * 500 | 300 | 3,600 | |

| Total | 4,300 | 51,600 | ||

Materials of Production

| Material | Ratio | Important Products | |

|---|---|---|---|

| FCD | 400, 450, 500, 550, 600, 700, 750S | 70.0% | MCV BODY, V/V BLOCK, V/V CASING, SPINDLE, ADV, HOUSING SADDLE, GEAR CASE, OIL PAN, D/CASE , CARRIER REAR FLANGE, CYL' BLOCK, S/ PLATE, SHAFT CASING |

| FC | 200, 250, 300 | 20.0% | SUPPORT, HYDRAULIC HOUSING, MISSION CASE MCV CAP SPOOL, CASING, PISTON BRAKE |

| FCV | 350, 400 | 10.0% | PUMP CASING (Reduce Noise), MCV Body Holding, MCV RCV Body |

| Ni_Special alloy | New | ○ Brake ring ○ Bearing Support ring ○ Amphibious wind Power Parts - Charpy impact results(test conditon -40℃) : 16~17Joule |

|

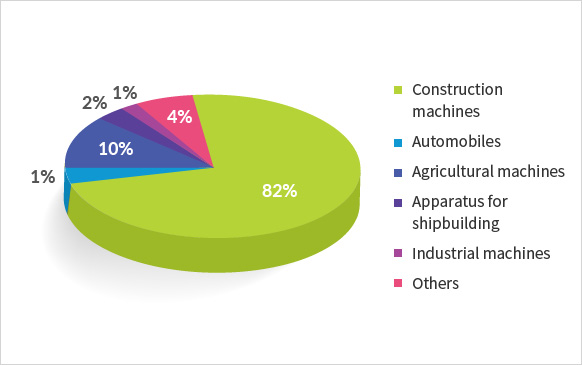

Share by Item

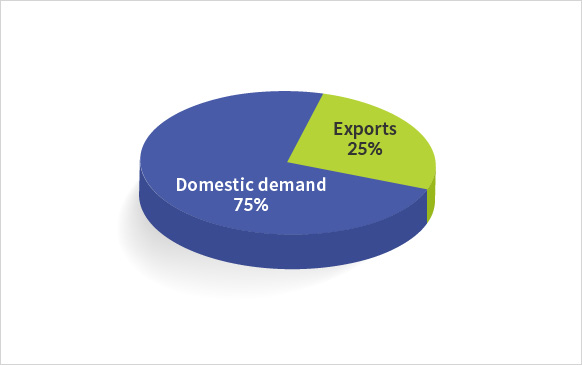

Share of Domestic Demand and Exports(%)